合作出成果:从大型项目到中等规模的成功。.

在建立良好声誉的同时,我们的目标是展示我们为中型项目提供高性价比解决方案的能力,向客户传授最新技术,确保他们取得长期成功。我们优先考虑与客户建立关系,而不仅仅是客户,经常与机场规划和开发部门的小型团队密切合作,以提供卓越的成果。.

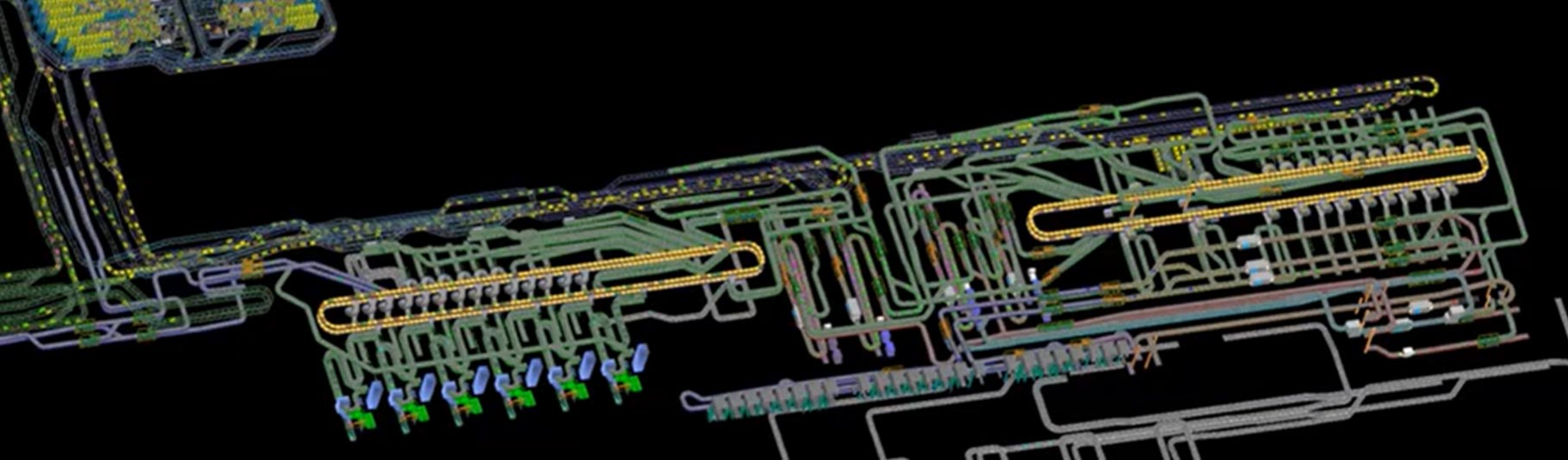

KAAN Architects retained BNP as part of an architecture and engineering consortium to design the new Terminal A at Schiphol International Airport in Amsterdam. BNP is responsible for designing the baggage handling system, which will function as an extension of the existing South Bag Hall, sharing logistics and capacity between the two systems. The terminal is designed to accommodate 24 million passengers per year.

The design needed to allow for an easy switch between origin-destination (OD) and hub-based operations. This required a flexible system that could support two different flight schedules. BNP conducted a detailed numerical analysis to identify the key requirements for the new baggage system.

The findings were used to define baggage demand and inform a multidisciplinary concept study that validated the terminal’s shape and size. Due to the system’s flexible design, the new terminal can share the large Early Bag Store (EBS) that is part of the South Bag Hall system. This reduces the footprint needed for the building if the OD scenario is selected.

Limited space and strong health and safety requirements from the stakeholders also led to the use of batch-processing technologies in the new terminal. Batching stations, using semi-automated loading, helped reduce the number of make-up positions while maintaining high make-up capacity.

BNP applied new technologies and processes to meet the high transfer, EBS, and make-up demands of Hub operations. Additionally, a strong interface with the existing bag halls was essential so both systems could work together for Hub operations or separately for OD, depending on the chosen mode.

To demonstrate that the system could handle the expected demand, BNP created a comprehensive 3D simulation of the proposed system. This included the existing South Bag Hall, the rack-based EBS, and the new batching process.

2018

Schiphol Group

欧洲