合作出成果:从大型项目到中等规模的成功。.

在建立良好声誉的同时,我们的目标是展示我们为中型项目提供高性价比解决方案的能力,向客户传授最新技术,确保他们取得长期成功。我们优先考虑与客户建立关系,而不仅仅是客户,经常与机场规划和开发部门的小型团队密切合作,以提供卓越的成果。.

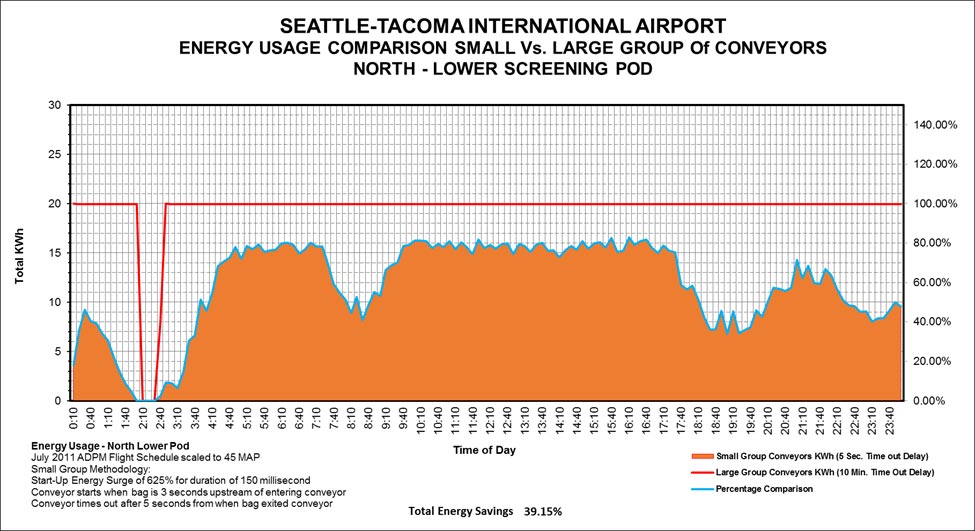

The electrical power required by motors to operate conveyors in a baggage handling system (BHS) is essential for designing the overall BHS. In many systems, numerous conveyors grouped into zones are started simultaneously due to the motor control configuration, such as soft starters, known as Zone Methodology. In this configuration, multiple conveyors are activated simultaneously, and they run continuously until the zone has been cleared of bags for a specified period, typically 10 minutes or more. This approach can result in running a large number of conveyors to transport a small number of bags during off-peak hours. The implementation of Variable Frequency Drives (VFDs) throughout the BHS eliminates the need for conveyor zones, allowing for targeted control and increasing energy efficiency by running motors only when necessary.

An alternative zoning strategy is the Small Group Methodology, where conveyors run only when bags are present. Downstream conveyors are activated seconds before bags reach them and deactivate a few seconds after the last bag exits. This method reduces unnecessary conveyor operation and achieves significant energy savings.

BNP uses simulation to verify the benefits of the Small Group Methodology. This approach involves activating motors when a bag approaches within a certain distance (configurable to three seconds of travel time) and deactivating them after the last bag exits the conveyor, with varying sleep delays (1, 2, 3, 5, and 600 seconds) examined. In contrast, the Zone Methodology simulation set a fixed sleep delay of 600 seconds for all conveyors. Energy consumption for each method was calculated over a 24-hour period.

The bag systems have been simulated using the Zone Method and the Small Group Method to quantify the runtime and the number of starts and stops of each conveyor. This data, combined with the motor energy requirements, is used to estimate the daily energy consumption of each approach. Simulations have identified opportunities to reduce airport energy costs by up to 33%. The graph below depicts the energy utilization for each methodology over the 24-hour study interval, showing significant energy savings with the application of the Small Group Methodology.

不适用

不适用

不适用