성과를 위한 파트너십: 대규모 프로젝트에서 중간 규모의 성공까지.

강력한 명성을 바탕으로 중규모 프로젝트를 위한 비용 효율적인 솔루션을 제공하고 고객에게 최신 기술을 교육하며 장기적인 성공을 보장하는 역량을 선보이는 것을 목표로 합니다. 공항 계획 및 개발 부서의 소규모 팀과 긴밀히 협력하여 탁월한 결과를 제공하는 등 고객뿐 아니라 고객과의 관계 구축에 우선순위를 두고 있습니다.

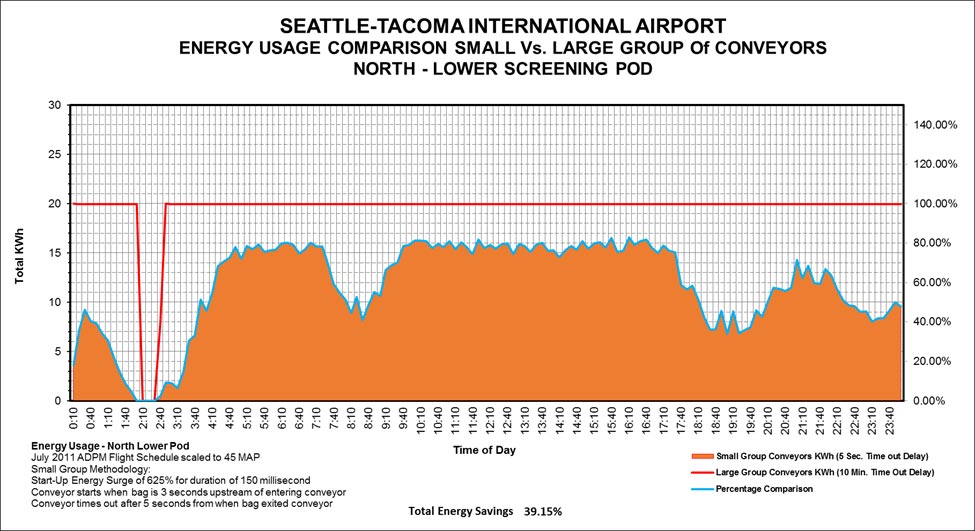

The electrical power required by motors to operate conveyors in a baggage handling system (BHS) is essential for designing the overall BHS. In many systems, numerous conveyors grouped into zones are started simultaneously due to the motor control configuration, such as soft starters, known as Zone Methodology. In this configuration, multiple conveyors are activated simultaneously, and they run continuously until the zone has been cleared of bags for a specified period, typically 10 minutes or more. This approach can result in running a large number of conveyors to transport a small number of bags during off-peak hours. The implementation of Variable Frequency Drives (VFDs) throughout the BHS eliminates the need for conveyor zones, allowing for targeted control and increasing energy efficiency by running motors only when necessary.

An alternative zoning strategy is the Small Group Methodology, where conveyors run only when bags are present. Downstream conveyors are activated seconds before bags reach them and deactivate a few seconds after the last bag exits. This method reduces unnecessary conveyor operation and achieves significant energy savings.

BNP uses simulation to verify the benefits of the Small Group Methodology. This approach involves activating motors when a bag approaches within a certain distance (configurable to three seconds of travel time) and deactivating them after the last bag exits the conveyor, with varying sleep delays (1, 2, 3, 5, and 600 seconds) examined. In contrast, the Zone Methodology simulation set a fixed sleep delay of 600 seconds for all conveyors. Energy consumption for each method was calculated over a 24-hour period.

The bag systems have been simulated using the Zone Method and the Small Group Method to quantify the runtime and the number of starts and stops of each conveyor. This data, combined with the motor energy requirements, is used to estimate the daily energy consumption of each approach. Simulations have identified opportunities to reduce airport energy costs by up to 33%. The graph below depicts the energy utilization for each methodology over the 24-hour study interval, showing significant energy savings with the application of the Small Group Methodology.

N/A

N/A

N/A