성과를 위한 파트너십: 대규모 프로젝트에서 중간 규모의 성공까지.

강력한 명성을 바탕으로 중규모 프로젝트를 위한 비용 효율적인 솔루션을 제공하고 고객에게 최신 기술을 교육하며 장기적인 성공을 보장하는 역량을 선보이는 것을 목표로 합니다. 공항 계획 및 개발 부서의 소규모 팀과 긴밀히 협력하여 탁월한 결과를 제공하는 등 고객뿐 아니라 고객과의 관계 구축에 우선순위를 두고 있습니다.

MNG 항공은 이커머스와 창고를 위한 두 개의 시설 개발을 위한 타당성 조사를 위해 BNP에 의뢰했습니다.

MNG 항공은 이커머스와 창고를 위한 두 개의 시설 개발을 위한 타당성 조사를 위해 BNP에 의뢰했습니다.

이커머스 시설의 경우 가용 부지, 기존 시설의 재사용 또는 개조 가능성, 자동화 수준을 기준으로 몇 가지 옵션을 평가했습니다. 이 프로젝트에서 흥미로운 도전 과제는 부지의 상당한 고저차(약 7미터), 분할된 부지, 기존의 상당한 유틸리티였습니다. 높은 수준의 비용 추정치를 포함하여 옵션을 평가하는 경영진 브리핑이 제공되었습니다.

제안된 기술은 트롤리에 연결된 슈트로 물품을 분류하는 크로스 벨트 분류 시스템의 스택 세트로 구성되었습니다. 트롤리는 무게가 추가될수록 낮아지는 유연한 바닥을 갖추고 있어 슈트에서 트롤리로의 낙하 거리를 줄여줍니다. 트롤리는 수동으로 이동하거나 소형 트랙터로 견인하거나 향후 무인운반차(AGV)로 취급할 수 있습니다. 시간당 15,000개의 물품을 100개의 슈트/목적지로 운반할 수 있습니다.

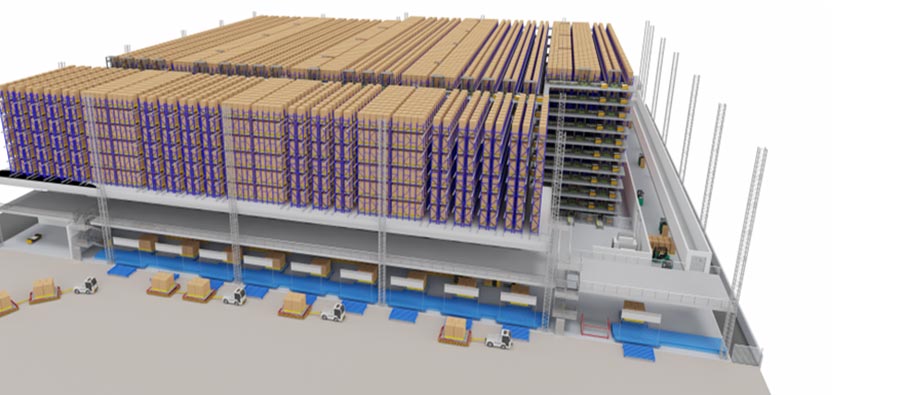

에어사이드 프리존 창고의 경우 부지는 고정되어 있었습니다. 하지만 운영 중단 없이 저비용 수동 작업에서 고처리량 자동화 프로세스로 전환하기 위해서는 높은 수준의 유연성이 요구되는 잠재적 비즈니스에 대한 불확실성이 있었습니다. 현장과 자동화를 극대화할 수 있는 궁극적인 용량은 37,000개의 팔레트 위치입니다.

이 창고에는 부수적으로 사용할 수 있는 보안 및 세관 기능이 포함되어 있습니다. ULD 브레이크를 통해 에어사이드에 직접 액세스할 수 있으며 주문부터 주문 처리까지 빠른 대응이 가능하도록 위치를 구축합니다.

2019

MNG 항공, 이스탄불 국제 공항(IST)

중동